Kitchen Manufacturing Queensland Business

Quick Facts

Payoff: 3.2 years

Projected savings after the first quarter: In excess of $20,000.00

System size: 50kW

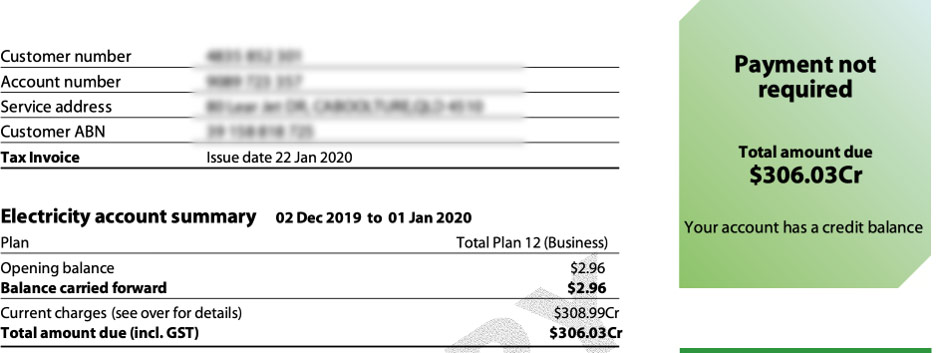

First power bill post tariff review: $306.03 credit

Kitchen Manufacturing Queensland Business Case Study Install of a 50kw Solar System

In 2017, OTI Power completed an installation for a kitchen manufacturing business in Queensland. The kitchen company is a high end design company that build personalised kitchens using their team of interior designers.

Although the company is branded a kitchen company, their team had extended their services to cater for all aspects of customers’ homes. The company had experienced significant growth in the manufacturing area which resulted in power consumption being up over 600% in 12 months.

The company works with customers from brief, to design, build and install. The factory is based on site which led the company to OTI Power to assist with reducing the power costs associated with the manufacturing arm of the business. The company was experiencing high power accounts to keep up with the customer demands while retaining all work in their factory.

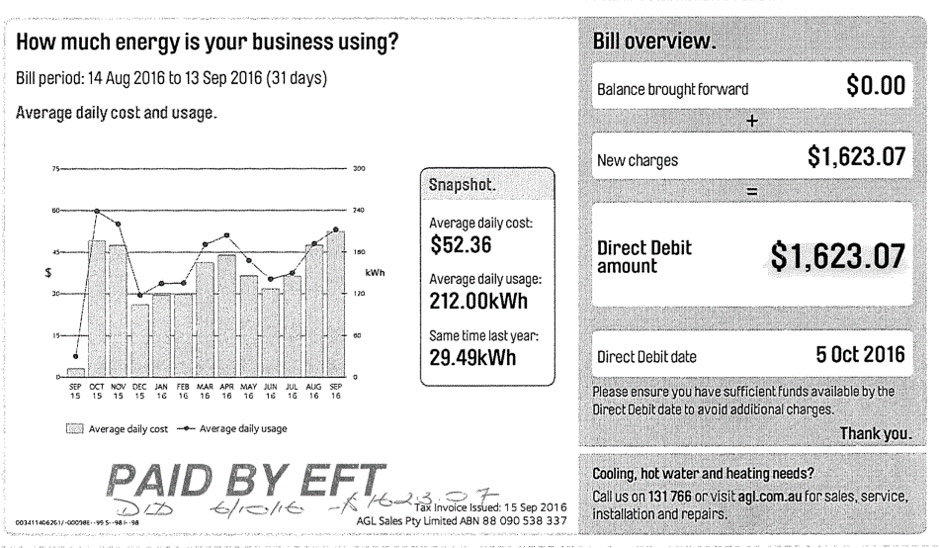

The initial meeting with the company quickly revealed that there power bill was over $52 per day on average at $1623.07 for 31 days. This account also revealed that the company’s average daily usage was up significantly on the same time 12 months ago. This presented a great opportunity for OTI Power to assist with strategies to reduce their power account.

The company’s manufacturing warehouse provided the perfect space to place the necessary solar system to offset the high energy bills. OTI Power predicted that the install of a 50kW solar system would provide all the necessary power requirements for the company. It was expected that the results would be almost immediate and, by following OTI Powers recommendation of a quality solar system installation, the results would be ongoing for many years to come.

The solar system that OTI Power recommended was a 50kw Solar PV System using 290W REC Twin Peak Panels with a Solar Edge Inverter. The team also recommended live monitoring so that the company could see at a glance production, output, input and any issues that were present.

Upon approval, the OTI Power team quickly acted and proceeded with installation. The installation process was a quick process taking OTI Power four days to complete. The team managed the install with minimal interruptions to the company with only one power outage throughout the process. The OTI Power team scheduled for this power outage to be carried out during non-manufacturing hours so that this had no impact on the operation of the business.

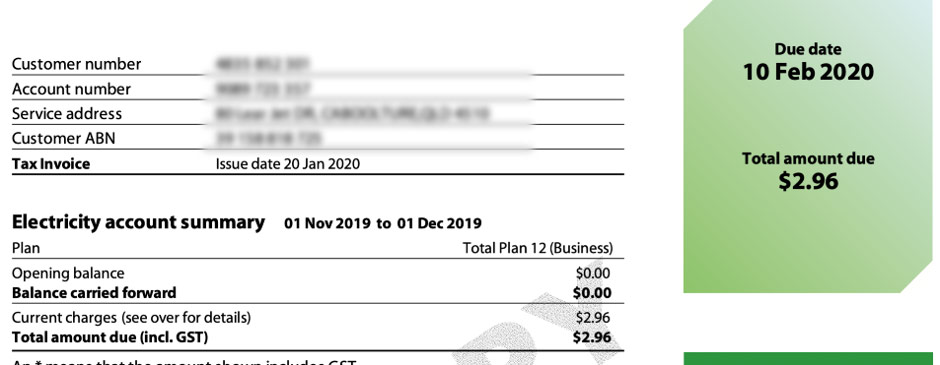

Following the successful installation of the solar system, OTI Power carried out a tariff review for the kitchen manufacturing company. This review identified that should the company source an alternate energy supplier, they could receive a greater rate for the excess solar that they were generating and returning to the system. The company took OTI Power’s advice regarding this change and this resulted in the company making additional income.

Four Months On

Four months post-install, the OTI Power team spoke with the kitchen manufacturing business and found out that their last power bill was $306.03 in credit. This was an amazing turn around. This demonstrated that the company was forecast to save over $20,000.00 per annum.

12 months on and the proof was in the power bills! The savings kept coming and the company was pleased to confirm a saving of over $20,000.00 after year one.

What was the cost?

The kitchen manufacturing businesses total investment was $53,000.00. The company received a Small Technology Certificate government rebate of $40,420 which is paid directly to OTI Power.

Total project cost: $93,420

Total cost to the kitchen company: $53,000

This investment will provide the company with a return in just on 3.2 years.